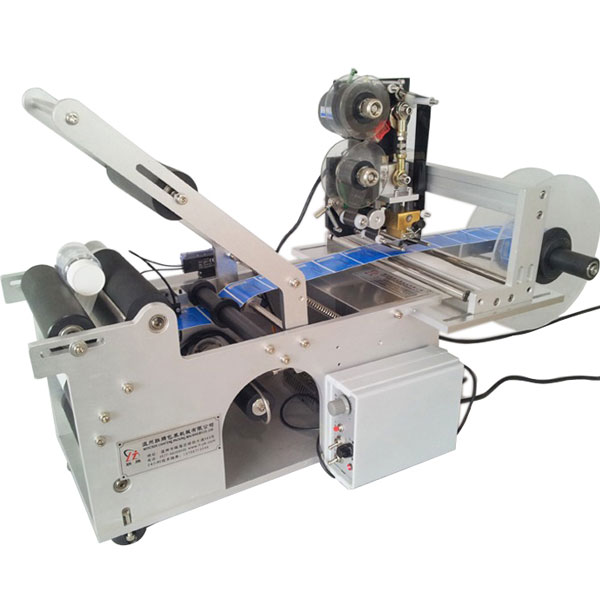

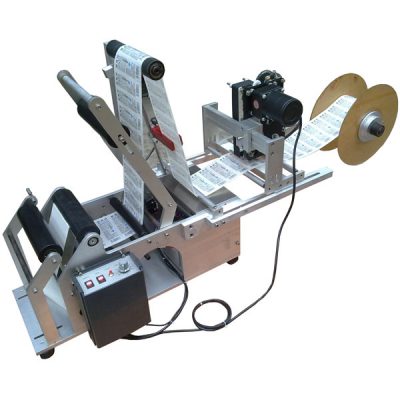

Description

Working principle

Imported intelligent high-accuracy magic eye and high reliable Computer chip program controller(PLC)control the label and the case, label, using rubber roller pinned bottle the non-drying label followed the bottle in the bottle and put on rotating.

Features

1. Applicable scope, can meet 10-100 mm diameter range of cylindrical considerate scale

2. High accuracy of labeling, the acuities of label head to tail connect local just reache + / – 0.5 mm

3. The clever extrusion type device feeding, just need to place the pieces,it can automatically labeling

4. The jockey for position type adjustment, different workpiece labels switching simple

5. Adopt the synchronous belt traction, mechanical stability is greatly improved

6. Desktop design, the structure is simplified, appearance compact, powerful

7. Using the anodic oxidation of aluminium alloy stents and advanced computer white box, the beauty is generous

8. Using advanced electric eye, the object, the label high detection sensitivity.

9. Labeling and printing combined in one machine,it can print the production date,batch number,valid time and other words on each label accuratlly,and then label it on the round bottle.

Technical parameters

1. efficiency: ≤50pcs/min

2. precision: ±1mm

3. Applicable bottles of diameter: Φ10-150mm

4. Label roll: external diameter: 300mm inner diameter: 36-76mm

5. Label size: width 8-150mm length 15-210mm

6. Power supply: 220V, 50HZ 120W

7. Machine size: 650*450*450mm

8. Machine weight: 40kg

Operation sequence

1. First installation 2 slices of organic glass tray, respectively in two round installation fixed block, and then you will take slot first set of fixed block nursery dish core shaft, the green o-rings pull to fixed block of the trough, again fixed block screwed.

2. Label installation: the installation rolls label, is direction in clockwise tag along the label, and put the label on the tray to carry the external fixation and lock screw.

3. According to the label will wear the good direction, clockwise around the label head of standard, the bottom standard core clamping device and head out label, the clamp the clamping DaoBiao cylinder lock, otherwise the machine will not work. In the lock DaoBiao clamping cylinder, should pay attention to label the wheel about balance rubber balance rubber balance degree, such as no balance, can appear about labeling the phenomenon of up and down after label. The paragraph tags and bottom mark after must wear on the same level, and put all the film cylinder on the positioning of the circle, to ensure the proper position guide are tags.

4. The power supply plugged into the single-phase power supply (requires a good ground connection).

5. The power supply switch on, adjust the magic eye: Tag magic eye is by amplifier and U fiber-optic first two parts, As shown in Figure:

First will U fiber-optic lines of the head of arbitrary insert fiber socket2 centimeters, Then lock, Will regulator counterclockwise transferred to the lowest position, The tag through u-shaped fiber u-shaped slot, Two pieces of the label on fiber position of interval between head, Then the clockwise turn the regulator, Rotating slowly from low to high, Until light so far,

Back-and-forth pull Label, Label when on optical fiber head, indicator light off, Again, that signals a stable fine-tuning. These steps are completed, already successful commissioning that label magic eye. General before they have been tested.

a. Magic eye position: Magic eye position is related to label stopped position, so stay to adjust its position. Different sizes of label the required position is different also, Magic eye if position too back, will appear label is too long, Cause label head cannot adsorption label. Magic eye position quite rely on ahead, Will appear tags too short, Cause tags do not have labeling.

b. label stopped position: Is the index sign in labeling strip out before the length of Stripper plate, By magic eye to control. General adjustment to label head traps by tags just can.

6. Adjust the position of positioning arm: Positioning the bottle on the shelf is positioned to play on the rubber roller can rotate the role of, Depending on the diameter of the bottle, to adjust for the location of the bottle.

7. Pressing down the arm pressure bottle, press to start switch to work, pressure on the arm of the pressure bottle Pressing rubber wheel will rotate week

While rotating the bottle labels adsorbed on the bottle body.

Notice

1. Operators first before use, please be sure to read the instruction

2. Important: Do not locate the bottle of rubber rollers in the case above, there is no pressure bottle pressure arm, otherwise the work will switch to crush!!!

Troubleshooting

1. Labeling action is not normal: Check the label position is normal, Transmission mechanism have labels or foreign bodies stuck.

2. Label head don’t fall or not rise: Check whether normal and stable source.

3. Label do not adsorb: Check whether normal and stable source.

4. Label rolled up: Cheek whether the blowing tube correctly position.

5. Waste paper receiver don’t pull: Check whether the state tension membrane too tight.

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.